In the development of biped robots, energy efficient locomotion via walking or running is a major research priority. Due to the limited energy storage (battery), energy efficiency significantly determines the walking distance that can be covered. Energy efficiency depends not only on the controller used for stabilizing the motion, but also on the structural design and its mechanical model parameters. Hence, the purpose of this research is to develop and apply a method to systematically optimize the structure of a bipedal robot to maximize energy efficiency in different environments.

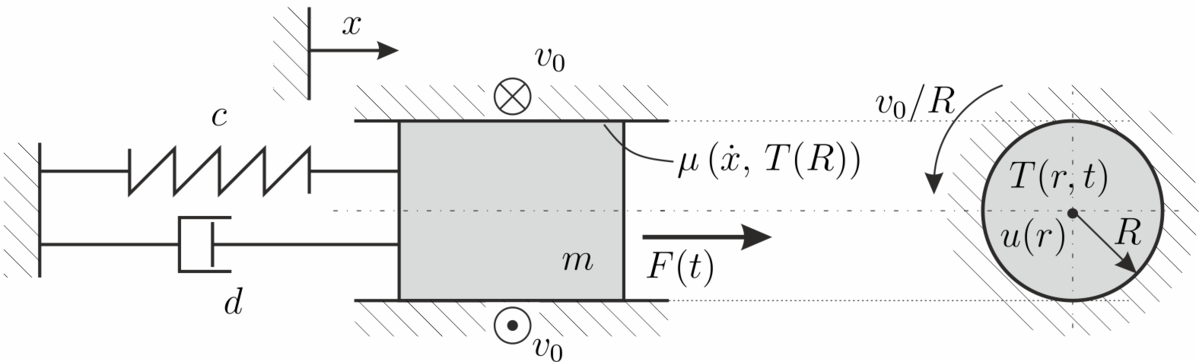

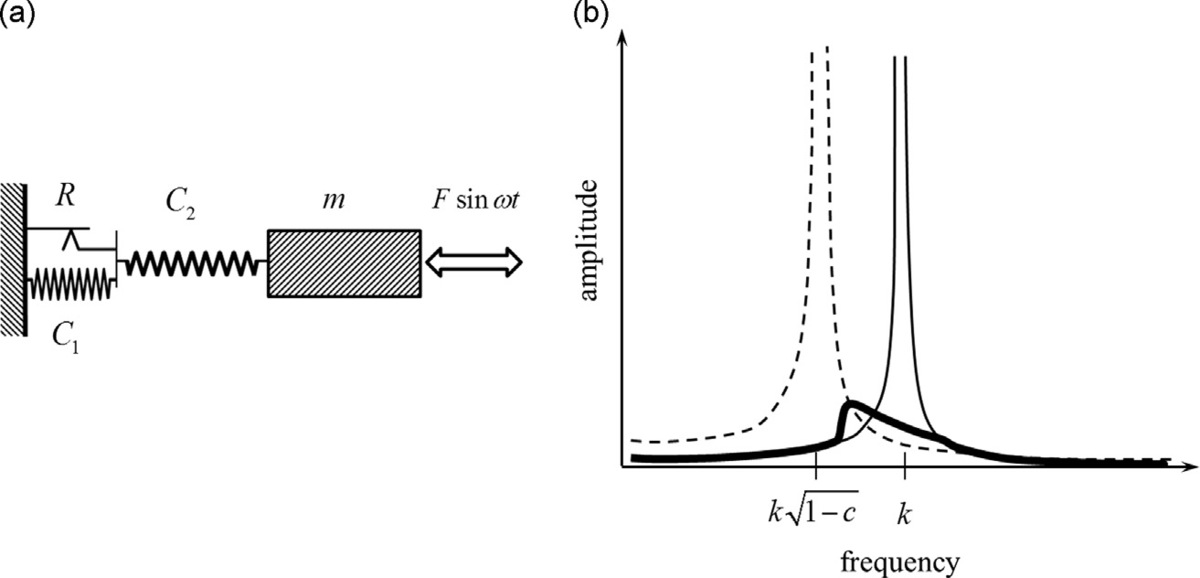

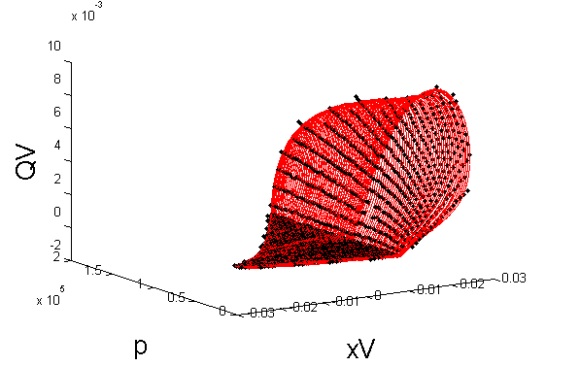

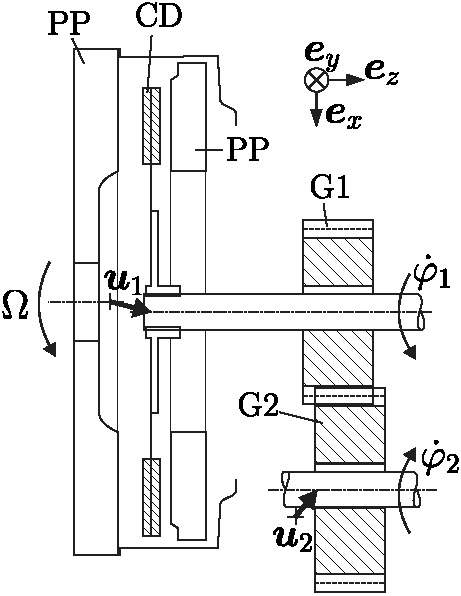

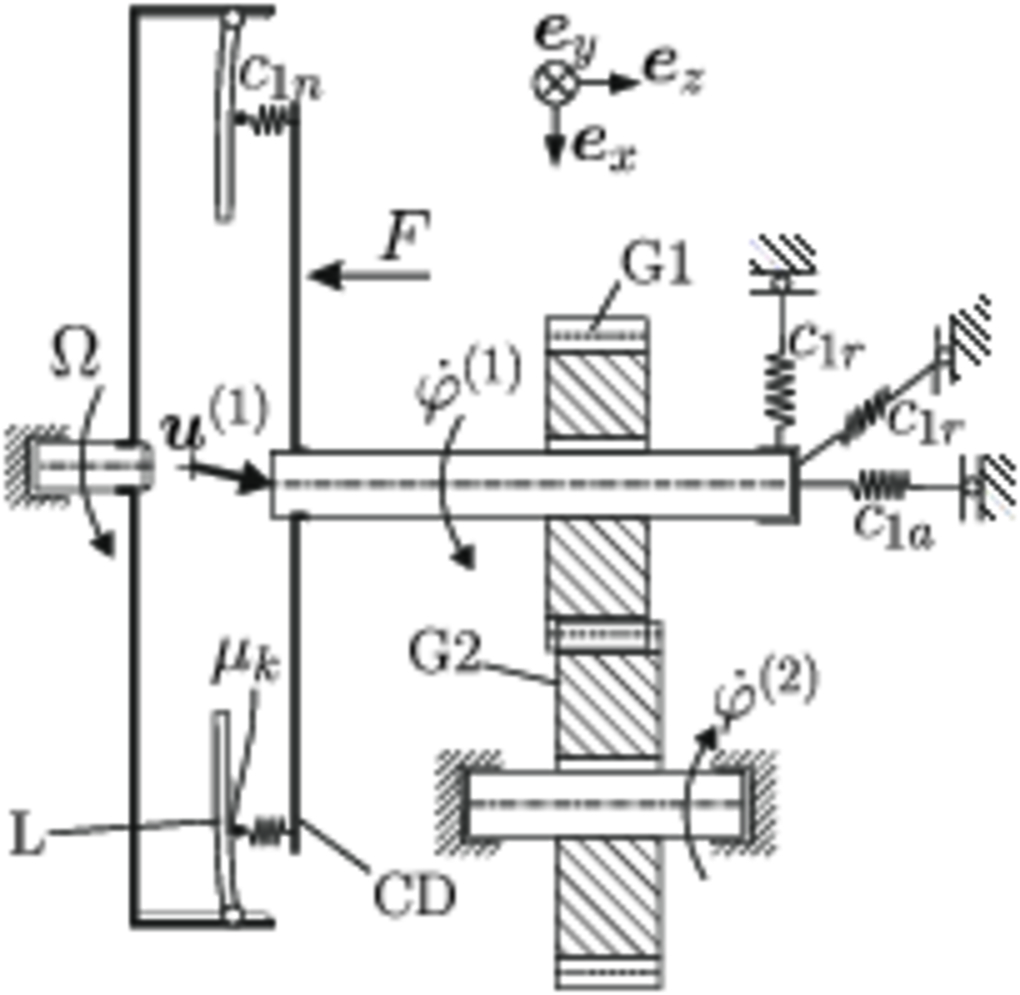

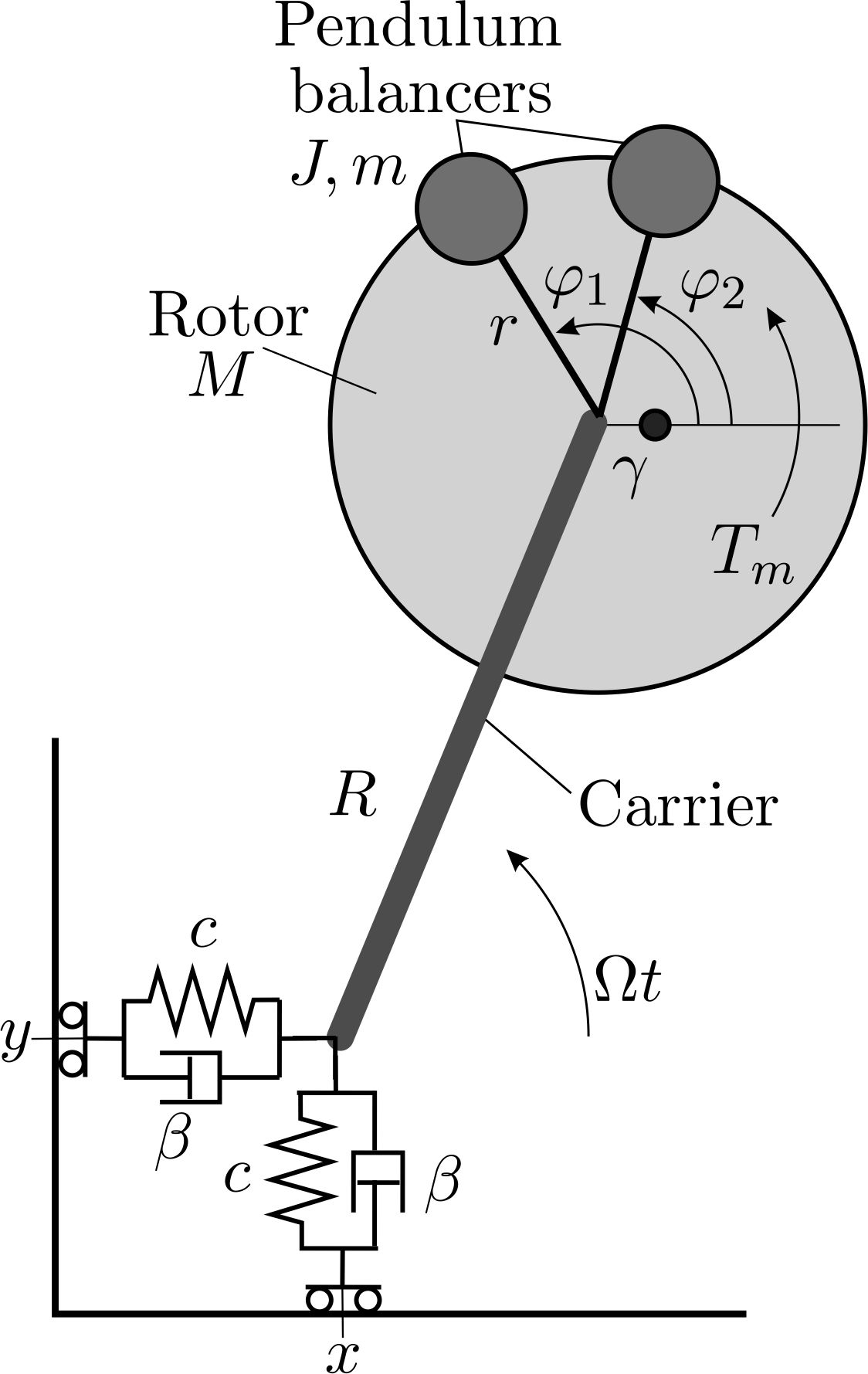

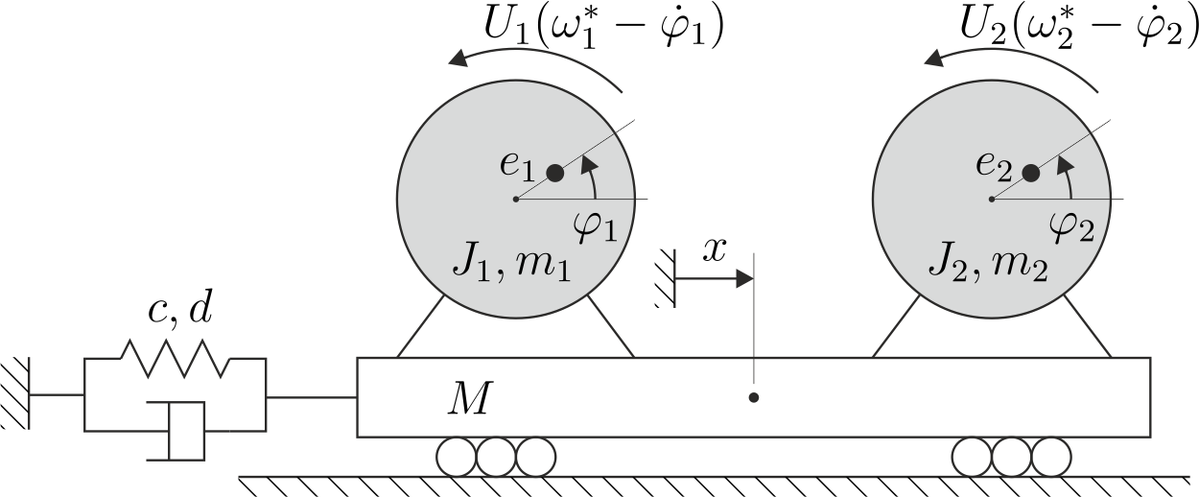

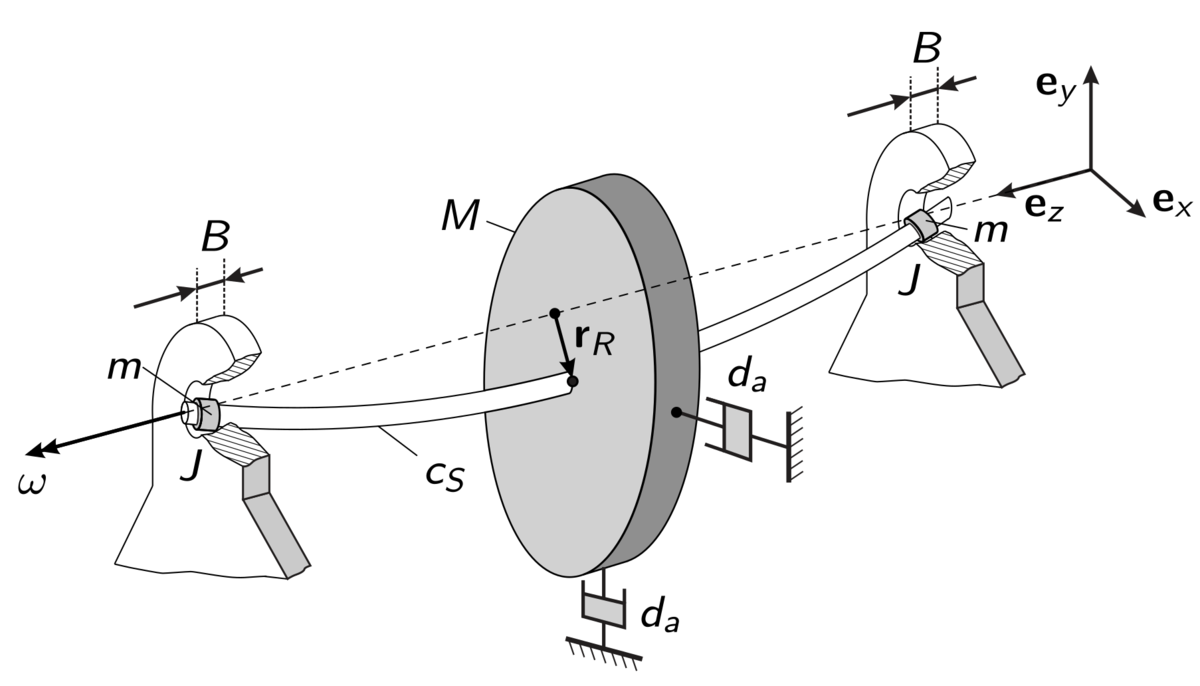

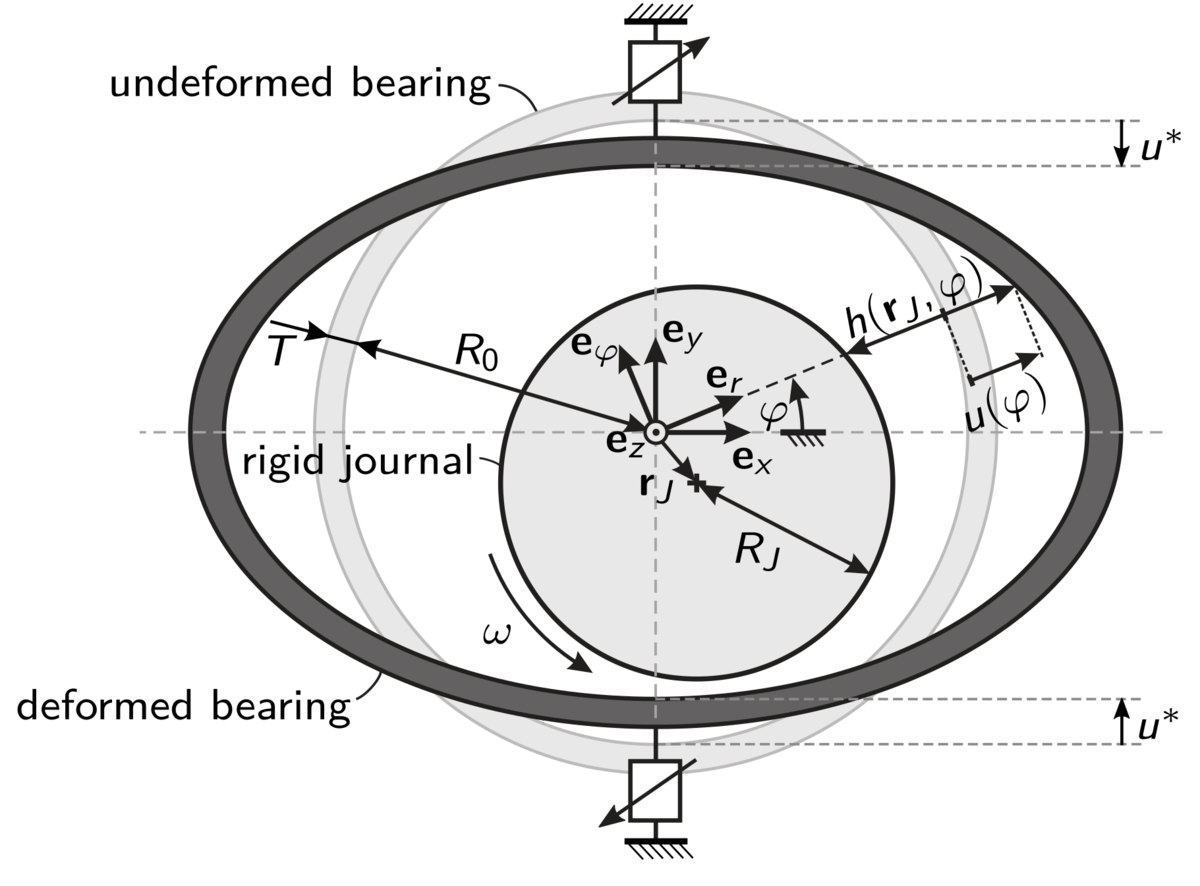

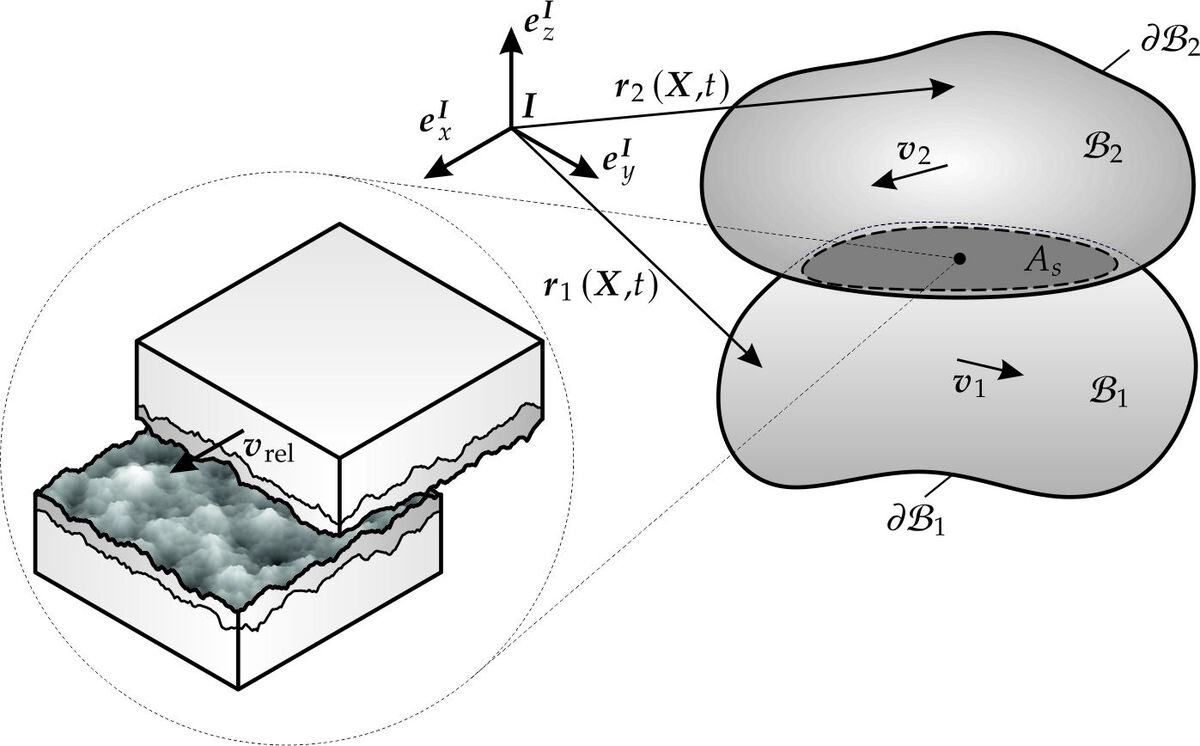

In the first step we consider an underactuated robot model which consists of five segments. Its rigid segments are additionally connected by elastic couplings such as torsion springs. Knowing that the robot’s periodic walking or running gaits can be analyzed as limit cycles of the controlled mechanical system, its resonance frequency can be adjusted to match the current step frequency by modifying the elastic couplings. A systematic approach to achieve this matching consists in the simultaneous optimization of the elastic couplings and the controlled motion. Consequently, the robot exploits the mechanical system's natural dynamics instead of wasting energy on its suppression.

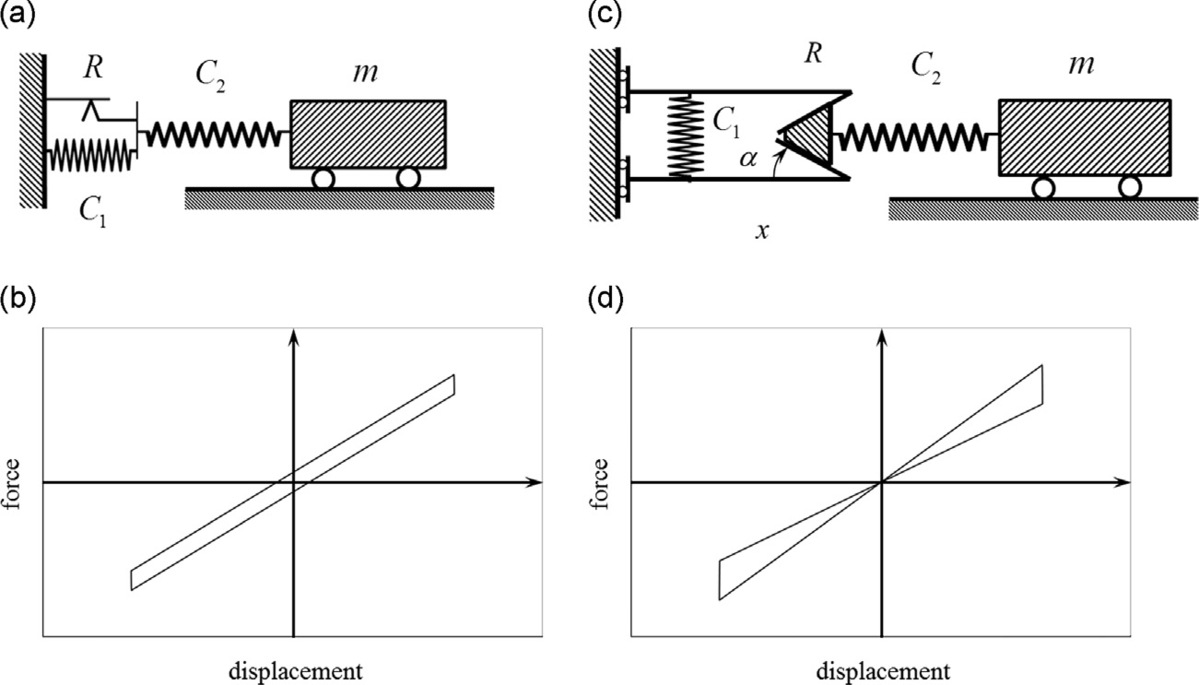

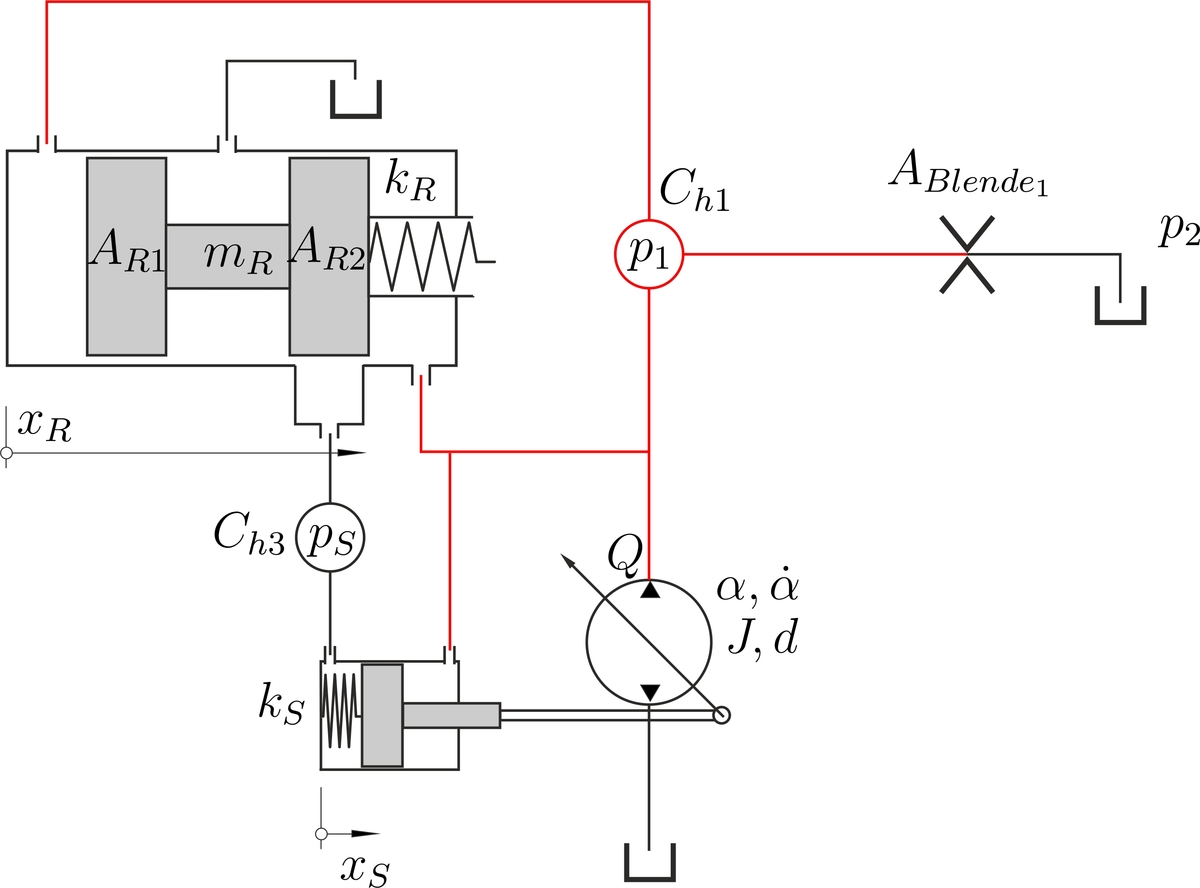

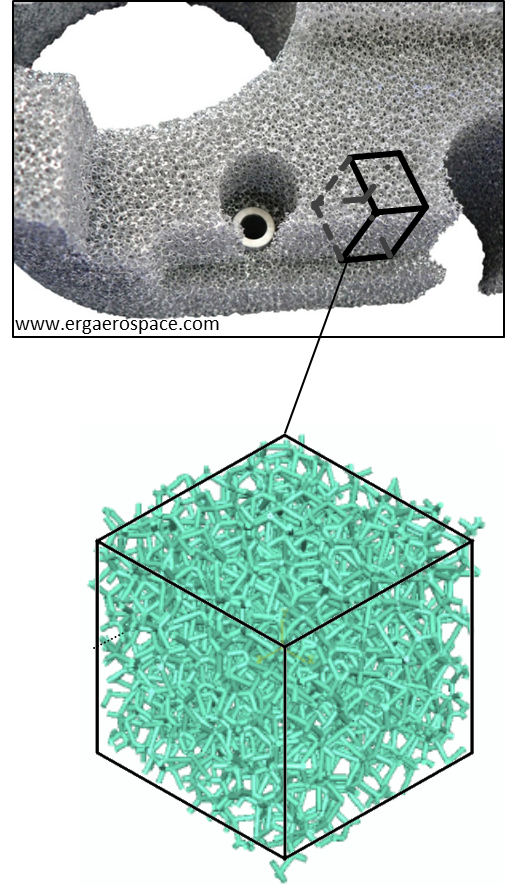

Since the optimization of the parameters essentially depends on the conditions of the environment and the gait, the focus is on how the adaptation of the robot to the current operating state can be realized. Unlike the motion, which can be continuously updated by the controller based on the measured state variables, the elastic couplings need to be optimized to achieve the best characteristics by using "compliant smart mechanics" (COSM). Between the stance and swing phases of the robot’s legs, and especially during switching processes of the movement, an optimal (force-displacement and/or force-velocity) characteristic of COSM leads to an overall high energy efficiency for a wide range of walking scenarios.

This project is being carried out jointly by two research groups: The Compliant Systems Group (FG NSYS) from the Ilmenau University of Technology (TU Ilmenau) and the Institute of Engineering Mechanics (ITM) from the Karlsruhe Institute of Technology (KIT). While the team at TU Ilmenau investigates the compliant mechanical systems and their design and implementation, the team at KIT simulates and optimizes bipedal robots with those COSM mechanisms in different environments. It is financially supported by the German Research Foundation (DFG), grant FI 1761/4-1 | ZE 714/16-1.

Project partner: Prof. L. Zentner ![]() , M. Zirkel

, M. Zirkel ![]() .

.

Contact: Prof. A. Fidlin, Dr. U. Römer, Y. Luo