A shift gearbox is a commonly used element in automotive transmissions, which is needed for two reasons. Firstly, it transmits the driving torque of the motor. Secondly, because a combustion engine works best at its nominal speed, it changes the gears. Experimental data reveal that in a shift gearbox, friction-induced vibrations are possible during the shifting period. The vibrations are visible in the pressure signal of the actuation of the clutch, which implies a coupling with the axial movement of the gear unit input shaft.

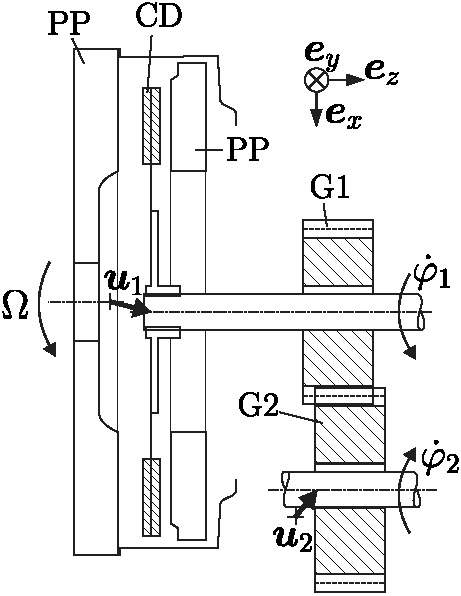

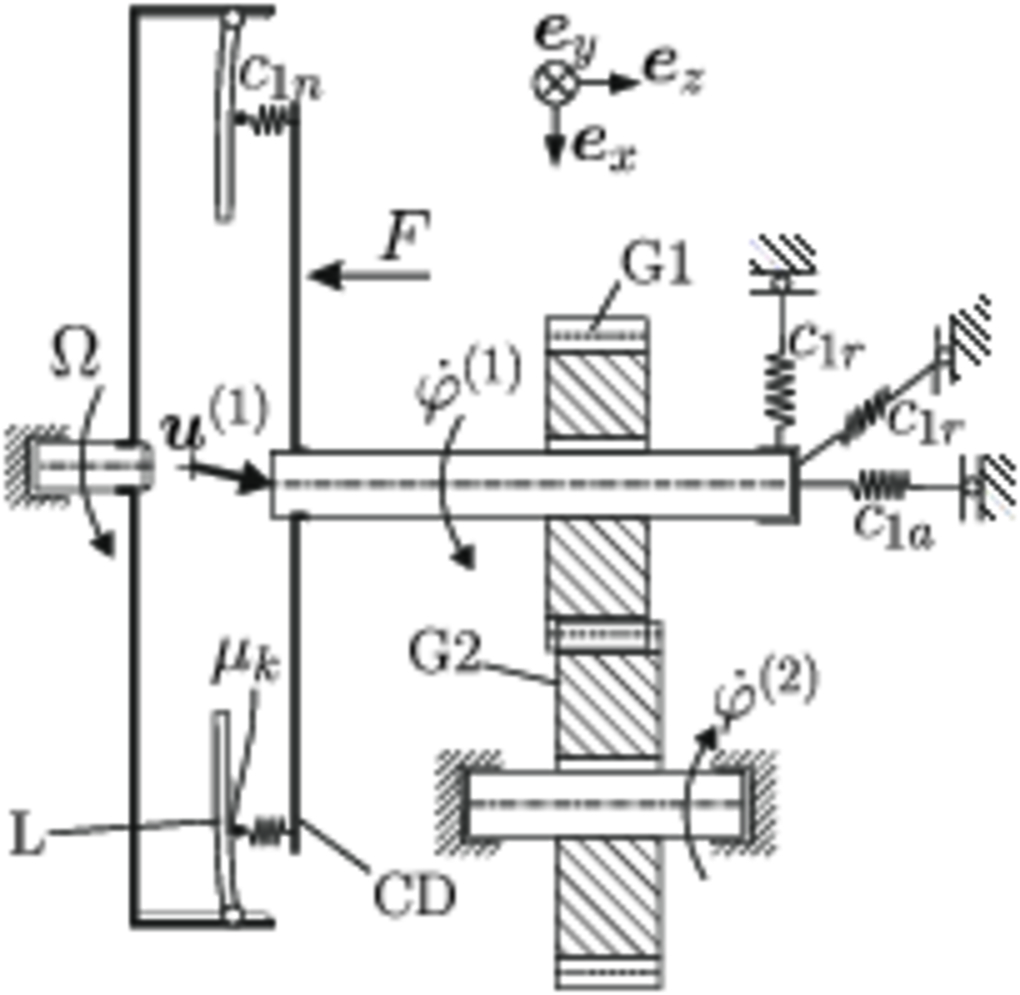

The suggested model consists of a pressure plate, a clutch disc, a gear unit input shaft and a tooth contact. The gear unit input shaft is rigidly connected to the gearing and the clutch disc and has translational and rotational degrees of freedom. The tooth contact imposes a kinematic constraint. This is why the sliding friction torque is transformed into forces in axial and radial direction of the shaft. Depending on the gearing parameters and the slip, the contact normal force between clutch disc and pressure plate is amplified (motor accelerating) or reduced (motor slowing down) by the toothing. For both shifting situations, there can be found a region of flutter instability in the parameter space.

Besides the stationary solution, also periodic orbits are possible. E.g. there exists a stable piecewise-continuous limit cycle for a slowing down motor: During one period, the contact between the clutch disc and the pressure plate opens shortly. This limit cycle depends on parameters (masses, stiffnesses, ...) as well as on operation conditions.

Contact: Prof. A. Fidlin