Nikola Lalović, M.Sc. M.Sc.

- Research Assistant

- Room: 302.1

CS 10.23 - Phone: +49 721 608-48133

- nikola lalovic ∂does-not-exist.kit edu

Karlsruher Institut für Technologie (KIT)

Kaiserstraße 10

76131 Karlsruhe

Curriculum Vitae

| since 09/2024 | Research assistant at the Institute of Engineering Mechanics - Continuum Mechanics, Karlsruhe Institute of Technology (KIT) |

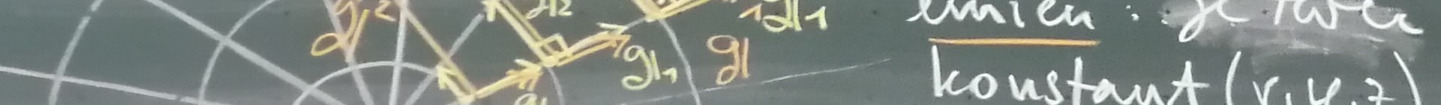

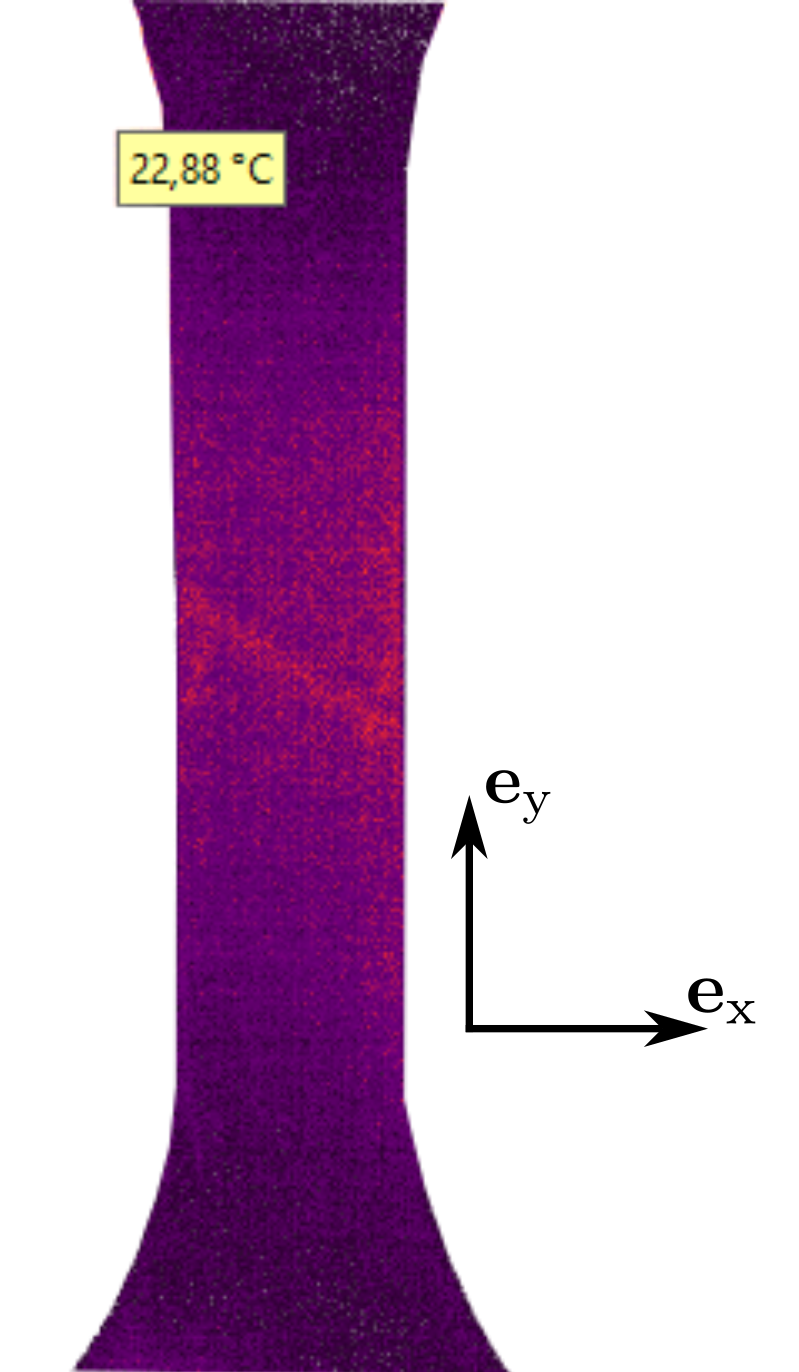

| 08/2023-02/2024 | Master thesis “Thermomechanical Coupling during Plastic Deformation of Metals”, in cooperation with the Institute of Applied Materials - Materials Science/Institute of Engineering Mechanics - Continuum Mechanics, (KIT) |

| 10/2020-09/2024 | Master's studies in Materials Science and Engineering (M.Sc.), specializing in Structural Materials and Computational Materials Science; Master's studies in Mechanical Engineering (M.Sc.), specializing in General Mechanical Engineering, with a focus on Reliability in Mechanical Engineering and Advanced Materials Modeling; Karlsruhe Institute of Technology (KIT)/Politecnico di Milano, Milan, Italy; graduated with distinction in both. |

| 09/2019-05/2020 | Internship and work experience in the field of decommissioning/deconstruction for EnBW Kernkraft GmbH in Philippsburg (Baden) |

| 10/2016-09/2020 | Bachelor's studies in Mechanical Engineering (B.Sc.), specializing in Materials Science and Materials Engineering, Karlsruhe Institute of Technolgy (KIT) |

Fields of Research

In my research, I investigate the heating of metallic materials during plastic deformation. While this phenomenon has been known for a long time (for example, continuously hammered iron retains heat for an extended period), gaps remain in its modeling and theoretical understanding. These gaps pertain both to the thermomechanical continuum description and to the connection with the defect structure of a material. Another challenge lies in experimental accessibility, as various studies employing different measurement techniques have yielded partially inconsistent results.

My approach is highly multidisciplinary and multimethodological, aiming to integrate thermomechanical continuum modeling with metallophysical perspectives while actively considering the relationship between theoretical descriptions and experimental observations. Through this, I seek to contribute to a more comprehensive understanding of the phenomenon – one that is both theoretically rigorous and experimentally verifiable.

The experimental method employed is based on in-situ thermographic measurements during deformation experiments, followed by the inverse solution of the heat equation using various approaches to determine heat sources. This knowledge is intended to also provide further insights into the structure of the yield surface in thermomechanical continuum models of metallic materials.

Talks

2025

Lalović, N.; Böhlke, T.

Identification of energetic and dissipative flow stress using infrared thermography.

41st Danubia-Adria Symposium on Advances in Experimental Mechanics, 23-26 September 2025, Kragujevac, Serbia

Lalović, N.; Böhlke, T.

Thermomechanical coupling and dislocation evolution: A framework for energy partitioning in plastic deformation.

XVIII International Conference on Computational Plasticity (COMPLAS 2025), 02-05 September 2025, Barcelona, Spain

Lalović, N.; Dyck, A.; Kauffmann, A.; Heilmaier, M.; Böhlke, T.; Estrin, Y.

Stress partitioning in thermoelastoplastic materials.

95th Annual Meeting of the International Association of Applied Mathematics and Mechanics, 07-11 April 2025, Poznań, Poland

2024

Böhlke, T.; Lalović, N.; Dyck, A.; Kauffmann, A.; Heilmaier, M.

Modeling and experimental determination of energetic and dissipative stresses in plastic deformation.

8th International Conference on Material Modelling, 15-17 July 2024, London, United Kingdom

Lalović, N., Dyck, A., Kauffmann, A., Heilmaier, M., Böhlke, T.:

Modeling and identifying yield stress and Taylor-Quinney factor using a thermodynamic consistent constitutive theory

and infrared thermography measurements

94th Annual Meeting of the International Association of Applied Mathematics and Mechanics, 18-22 March 2024, Magdeburg, Germany

Courses

Winter Semester 2025/2026

- Übung zu Technische Mechanik I (TM I)

- Tutorial Computational Mechanics of Materials (CMoM)

Summer Semester 2025

- Tutorial Engineering Mechanics II (EM II)

- Übung zu Rechnergestütze Kontinuumsmechanik (RKM)

- Praktikum in experimenteller Festkörpermechanik (PEFM)

Winter Semester 2024/2025

- Tutorial Engineering Mechanics I (EM I)